- Ameya360 Component Supply Platform >

- Trade news >

- ROHM's New Zero-Drift Op Amp with High Accuracy Regardless of Temperature Changes

ROHM's New Zero-Drift Op Amp with High Accuracy Regardless of Temperature Changes

ROHM has developed a zero-drift operational amplifier (op amp) - the LMR1002F-LB. It is designed for industrial and consumer electronics devices and minimizes both input offset voltage and input offset voltage temperature drift. Capable of accurately amplifying output signals from sensors installed in various measurement devices, this new op amp is ideal for current sensing applications such as power control inverters and temperature/pressures/flow/gas detectors.

As automotive and industrial equipment become more sophisticated and application control requirements are more precise, environmental sensors are increasingly being used to quantify temperature, pressure, and gas concentrations such as carbon dioxide to foster a sustainable society. However, sensor signals are so small that amplification is necessary, and if a general op amp with 1mV offset voltage is used to amplify the sensor signal by a factor of 1,000, for example, the offset voltage also increases by this amount - resulting in a voltage error of 1V (1,000mV) in the signal output. At the same time, input offset voltage temperature drift, which varies according to temperature and time, is difficult to compensate for.

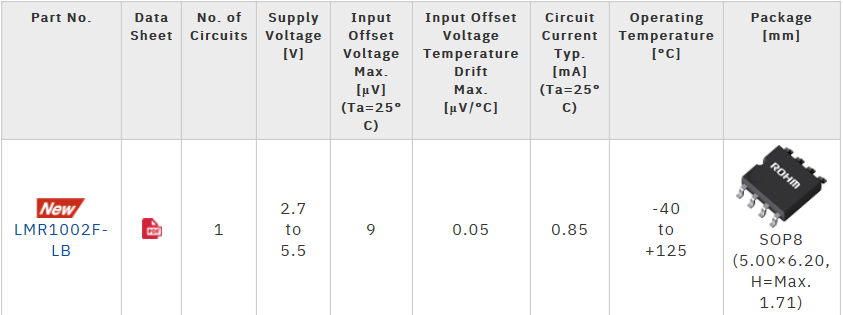

In response, ROHM developed a zero-drift op amp that addresses these problems by leveraging proprietary analog circuit technology - cultivated over many years. The LMR1002F-LB is ROHM’s first zero-drift op amp using the chopper method. In contrast to conventional low-offset op amps featuring a typical input offset voltage of 150µV (Max.), ROHM’s new product limits input offset voltage to just 9µV (94% lower). This eliminates the need for peripheral components or software to adjust the input offset voltage, reducing both design person-hours and costs. On top, input offset voltage temperature drift is just 0.05µV/°C (Max.) in the operating temperature range of -40°C to +125°C - the lowest among ROHM’s op amps. Enabling accurate amplification of measured sensor signals without being affected by environmental changes such as temperature contributes to high accuracy control of industrial equipment in factories. This, coupled with a wide supply voltage range of 2.7V to 5.5V and rail-to-rail input/output, make it ideal for a variety of industrial applications.

Going forward, ROHM will continue to improve the performance and expand its lineup of zero-drift op amps. Moreover, ROHM will work to improve the performance of op amp lineups by reducing noise and offset - while increasing power savings, and expand the power supply voltage range demanded in the automotive and industrial equipment markets. The overall goal: contributing to solving social issues through higher accuracy application control.

Product Lineup

Application Examples

• Industrial equipment: Power control inverters, photovoltaic inverters, storage battery monitoring, pressure gauges, flow meters, temperature controllers, gas detectors, etc.

• Consumer appliances: Refrigerators, washing machines, air conditioners, etc.

Online Sales Information

Sales Launch Date: December 2023

Pricing: $8.0/unit (samples, excluding tax)

The product will be offered at other online distributors as it becomes available.

■Product Information

Applicable Part No: LMR1002F-LB

Terminology

Input Offset Voltage

Refers to the error voltage that occurs between the input terminals of an op amp.

Input Offset Voltage Temperature Drift

The fluctuation in input offset voltage caused by a rise/fall in temperature. The smaller this value is the higher the op amp accuracy. Zero-drift op amps automatically compensate for input offset temperature drift.

Chopper Circuit

A circuit configured to detect the offset voltage generated inside an op amp and automatically correct it via digital circuit control. This cancels offset voltage by feeding back the offset voltage stored as capacitance in the circuit using a voltage-current conversion circuit.

Rail-to-Rail Input/Output

A circuit format that allows the input and output voltages of an op amp to accommodate the entire supply voltage range. The supply voltage in this case is called a Rail.

Online messageinquiry

Industry’s Highest* Rated Power! ROHM Unveils the UCR10C Series of Sintered Metal Shunt Resistors

- Week of hot material

- Material in short supply seckilling

| model | brand | Quote |

|---|---|---|

| TL431ACLPR | Texas Instruments | |

| MC33074DR2G | onsemi | |

| RB751G-40T2R | ROHM Semiconductor | |

| BD71847AMWV-E2 | ROHM Semiconductor | |

| CDZVT2R20B | ROHM Semiconductor |

| model | brand | To snap up |

|---|---|---|

| BU33JA2MNVX-CTL | ROHM Semiconductor | |

| IPZ40N04S5L4R8ATMA1 | Infineon Technologies | |

| TPS63050YFFR | Texas Instruments | |

| ESR03EZPJ151 | ROHM Semiconductor | |

| STM32F429IGT6 | STMicroelectronics | |

| BP3621 | ROHM Semiconductor |

- Week of ranking

- Month ranking

Qr code of ameya360 official account

Identify TWO-DIMENSIONAL code, you can pay attention to

Please enter the verification code in the image below: