- Ameya360 Component Supply Platform >

- Trade news >

- Nidec Machine Tool Develops World-first Polish (Grinding) Method to Process Internal Gears for Mass-production

Nidec Machine Tool Develops World-first Polish (Grinding) Method to Process Internal Gears for Mass-production

Nidec Machine Tool Corporation (“Nidec Machine Tool” or the “Company”), a group company of Nidec Corporation, today announced that it has developed the world’s first high-accuracy polishing (grinding) method to machine internal gears for mass production that are used for automobiles’ drive units and transmissions and for robots’ joints. While there are already high-accuracy polish-machining methods for external gears for mass-production, no such methods have been available for internal gears. After conducting research focused on this point, the Company has achieved positive results to secure the level of accuracy and production that conventional grinding, honing, or skiving methods could not.

Though the planetary gear mechanism boasts such merits as high efficiency, high load capacity, and compactness, gears used in the mechanism are required to be high-quality, as even a slight distortion in the gears as the mechanism’s components affects the durability and transmission efficiency, and may cause noise and vibration. As a growing number of products become electrified and automated, and as the needs for highprecision gears increase accordingly, the Company has realized this new machining method fast, and release it to contribute to improving gears’ durability, transmission efficiency, and NVH (noise, vibration, and harshness) performance.

This latest R&D project identified and derived machining conditions based on Nidec Machine Tool’s processing machines and technologies. This project is part of the joint research with Germany’s RWTH Aachen University. For more details on the project, please see the attached paper.

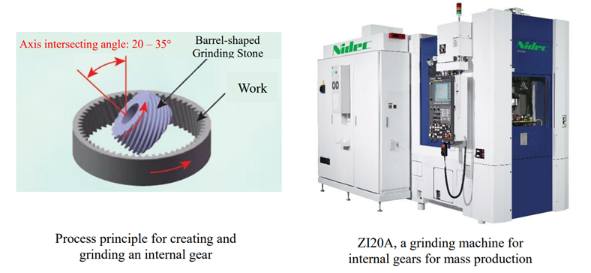

Processing machine: The Company used ZI20A, the grinding machine that it used its unique technology and launched in 2009 for internal gears for mass production. This machine can process internal gears with high precision to the degree of productivity required for their mass production.

Selection of grinding stones for polishing: The Company selected grinding stones, which are consumables, based on its preliminary assessment of their availability, economic efficiency, and suitability for autonomous driving.

Specifying machining conditions: By targeting Ra0.1µm and Rz1.0µm or less (a general surface roughness index for polish machining), the Company derived high-efficiency machining conditions that would maintain the post-polish gear accuracy of ISO levels 3 - 5, while preventing grinding burn.

With its world-leading gear-machining technology, Nidec Machine Tool provides machines, tools, and machining solutions to stay committed to contributing to solving social issues.

Online messageinquiry

- Week of hot material

- Material in short supply seckilling

| model | brand | Quote |

|---|

| model | brand | To snap up |

|---|

- Week of ranking

- Month ranking

Qr code of ameya360 official account

Identify TWO-DIMENSIONAL code, you can pay attention to

Please enter the verification code in the image below: