Nidec Machine Tool Adds Two New Models to The MV-BxII Series, Double-Column Machining Centers with Best-in-class Productivity

- A wide type MV16BxII, (1.7 x 2.2m) and a long type MV12BxII, (1.3 x 3.0m) are available now.

- Both models boast a low environmental load running cost due to their ECO operations

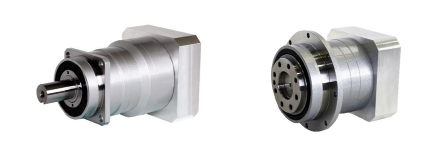

Nidec Machine Tool Corporation (“Nidec Machine Tool”) (President: Haruhiko Niitani; Head office: Ritto, Shiga), a group company of NIDEC, announced two new models of double-column machining centers, MV16BxII (1.7 x 2.2m) and MV12BxII (1.3 x 3.0m) go on sale today, Friday, December 01, 2023. Compared to MV12BxII (launched in February this year), MV16BxII (1.7 x 2.2m) has 400mm wider y axis movement and MV12BxII (1.3 x 3.0m) has 1,400mm wider x axis movement. Both 2 models follows the basic concept of MV12BxII, “Meet the machining needs of all industries,” and achieved the best-in-class rapid traverse for each axis 32m/min., shortening the non-machining time significantly. Additionally, utilizing the ECO operation technology to save power and reduce running cost, these highly productive and ecofriendly machines are capable of meeting the needs of various production sites.

MV16BxⅡ, one of Nidec Machine Tool’s latest double-column machining centers

MV16BxII (1.7×2.2m), a compact, double-column machining center equipped with a No.50 spindle, boasts a maximum main axis rotating speed of 7,000min-1 and realized the rapid traverse of 32m/min. for each axis (Ⅹ, Y, and Z), to shorten non-cutting time. In addition, to accommodate heavy work pieces (maching parts), the maximum loading capacity is set to 8t. MV16BxII has a structure that can suppress deflection by equipping three lines of linear guides on its X axis and realizes stable machining even in high-speed operations. MV12BxII (1.3×3.0m), the other new model, retains the same basic performance from its predecessor, while having a 3,000mm-long table and increasing the maximum loading mass to 5t. Both models are capable of handling larger work pieces and operate more productively than the previous model, MV12BxII (1.3 x 1.6m).

As is the case with all the other MV-BxII series models, MV16BxII and MV12BxII use the all-axis ball-screw axis- core cooling technology for high-precision machining, while their double-anchor mechanism ensures both high-speed movements and high rigidity. These features enable the two models to secure high heavy duty machining performance and high accuracy and achieve high productivity in rough through finish processing.

Furthermore, for ECO operations common to all the MV-BxII series models, MV16BxII and MV12BxII adopt electric power units to dramatically reduce electric consumption, and use grease lubricant agent for their main and feeding axes to reduce the running cost of air, lubricant agent, etc., and decrease work load during component replacements.

Both MV16BxII and MV12BxII, the latest additions to the MV-BxII series, were developed jointly with Nidec OKK Corporation, whose product lineup covers small- and mid-size machining centers. By utilizing the two companies’ technologies in combination for the models’ main units, main axis’ structures, and other elements, we were able to secure credibility in these products and a shorter procurement lead time to expand our product lineup. Nidec Machine Tool stays committed to quickly developing and brining to the market products that meet their users’ needs.

在线留言询价

- 一周热料

- 紧缺物料秒杀

| 型号 | 品牌 | 询价 |

|---|---|---|

| TL431ACLPR | Texas Instruments | |

| BD71847AMWV-E2 | ROHM Semiconductor | |

| RB751G-40T2R | ROHM Semiconductor | |

| MC33074DR2G | onsemi | |

| CDZVT2R20B | ROHM Semiconductor |

| 型号 | 品牌 | 抢购 |

|---|---|---|

| BP3621 | ROHM Semiconductor | |

| TPS63050YFFR | Texas Instruments | |

| STM32F429IGT6 | STMicroelectronics | |

| IPZ40N04S5L4R8ATMA1 | Infineon Technologies | |

| BU33JA2MNVX-CTL | ROHM Semiconductor | |

| ESR03EZPJ151 | ROHM Semiconductor |

- 周排行榜

- 月排行榜

AMEYA360公众号二维码

识别二维码,即可关注