Ultra-Compact Low Profile 2-Color Chip LEDs

Rohm officially licensed Online sales platform

Ameya360 Components Supply Platform www.ameya360.com

Click here for purchase:http://www.ameya360.com/product/6772067

Kyoto and Santa Clara, Calif., – August 24, 2017 – ROHM has recently announced the availability of the industry's smallest class (1608 size) of 2-color chip LEDs. In addition to their breakthrough size, the SML-D22MUW features a special design that improves reliability along with a backside electrode configuration that supports high-resolution displays.

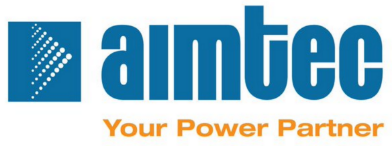

In recent years, chip LEDs are being increasingly used for numerical displays in industrial equipment and consumer devices. Conventional numerical displays utilize a single color to indicate numbers, but there is a growing need to change the color to make it easier to recognize abnormalities. However, this typically entails utilizing two separate LEDs, which doubles the mounting area along with development costs, or opting for a standard 2-color LED that also increases board size.

In contrast, proprietary technologies and processes allowed ROHM to integrate 2 chips in the same package size as conventional single-color LEDs, making it possible to emit multiple colors in a smaller footprint. Board space is reduced by 35% over standard 1.5 x 1.3mm 2-color LEDs, contributing to thinner displays. And after taking into consideration usage conditions during reflow, countermeasures were adopted that prevents solder penetration within the resin package to ensure greater reliability.

Availability: Now

Pricing: $0.136/unit (3,000pcs)

Key Features

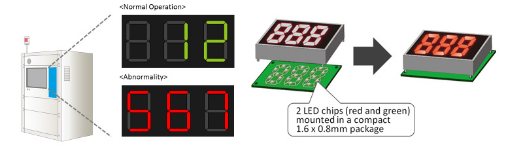

1. Class-leading compact size contributes to smaller, thinner devices

In addition to element miniaturization, the SML-D22MUW leverages PICOLEDTM mounting and wire bonding technologies to mount 2 chips (red and green) in a compact 1.6 x 0.8mm package – the same size as conventional single-color LEDs.

Also, the extremely close configuration of color elements results in excellent color mixing properties that make it possible to produce not only red and green colors, but a number of intermediate colors as well.

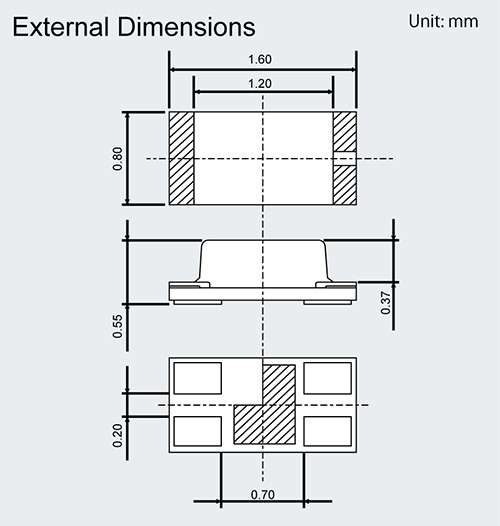

2. Solder penetration countermeasure ensures superior reliability

Incorporating a stopper called a ‘resist' before the gold plating process blocks the gold pattern (that features good wettability). This prevents solder penetration into the resin, eliminating failures due to short-circuits and contributing to greater reliability.

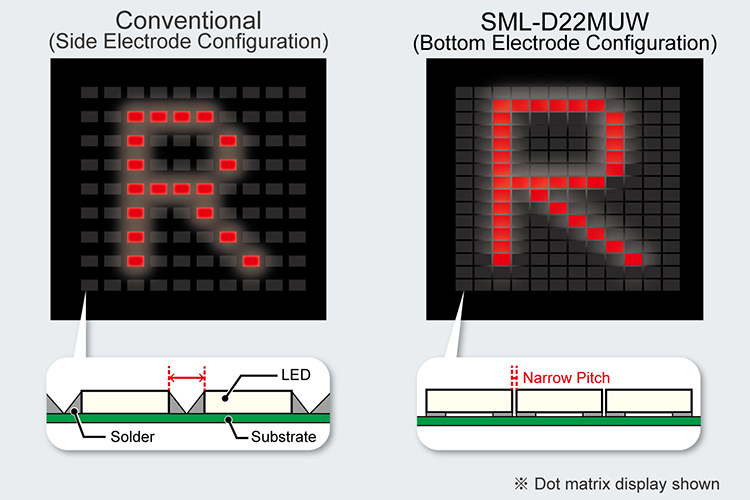

3. Backside electrode configuration supports high-resolution display

Adopting a backside electrode design allows mounting in narrow spaces, enabling high-definition display in dot matrix and other applications.

Backside Electrode Configuration

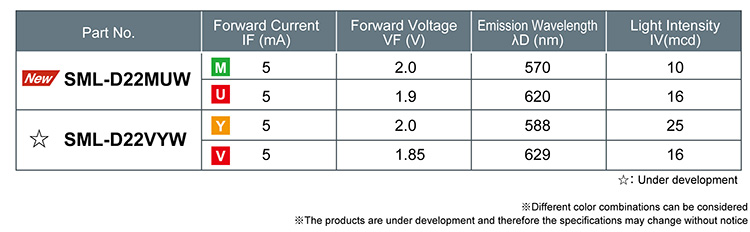

Lineup

Terminology

PICOLED™

ROHM's ultra-compact LEDs ideal for portable equipment such as wearables and mobile devices.

在线留言询价

- 一周热料

- 紧缺物料秒杀

| 型号 | 品牌 | 询价 |

|---|---|---|

| TL431ACLPR | Texas Instruments | |

| MC33074DR2G | onsemi | |

| CDZVT2R20B | ROHM Semiconductor | |

| BD71847AMWV-E2 | ROHM Semiconductor | |

| RB751G-40T2R | ROHM Semiconductor |

| 型号 | 品牌 | 抢购 |

|---|---|---|

| STM32F429IGT6 | STMicroelectronics | |

| BP3621 | ROHM Semiconductor | |

| IPZ40N04S5L4R8ATMA1 | Infineon Technologies | |

| BU33JA2MNVX-CTL | ROHM Semiconductor | |

| ESR03EZPJ151 | ROHM Semiconductor | |

| TPS63050YFFR | Texas Instruments |

- 周排行榜

- 月排行榜

AMEYA360公众号二维码

识别二维码,即可关注